Visualize LOPA calculations

Spreadsheets are hard to read. Make your LOPA study visual and easier to understand.

Spreadsheets are hard to read. Make your LOPA study visual and easier to understand.

Make your LOPA calculations more realistic by taking into account all bowtie scenarios when calculating the frequency of the top event.

Frequencies and probabilities can change over time. LOPA plugin allows you to calculate current and future frequencies.

Bowtie diagrams give a better understanding of your risk scenarios and show how these are controlled. In classic bowtie modeling, the decision as to whether there are sufficient effective barriers to control these scenarios is based on expert judgment.

When your organization has reliable and sufficient safety data available, the LOPA feature will allow you to use this data to make more objective and substantiated decisions.

Layers of Protection Analysis (LOPA) is a semi-quantitative risk analysis methodology. Hereby the frequency of a negative event is calculated according to the risk reduction delivered by the independent protection layers (barriers).

The LOPA feature automatically calculates the frequency of a consequence, given the initial frequency of all the threats and the Probability of Failure on Demand (PFD) of the barriers. This allows you to easily compare the target consequence frequency with the reality of daily operations.

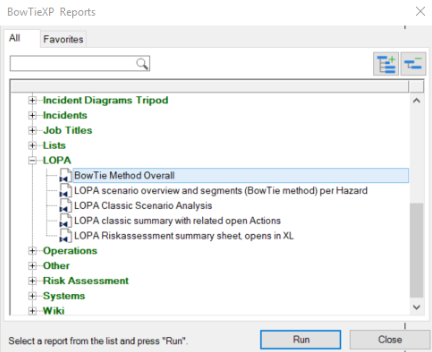

Make your risk calculations visible with the LOPA feature in BowTieXP Complete and put them in an easy-to-understand, barrier based perspective.

Courses & events

Courses & eventsLooking for an opportunity to discuss the LOPA feature in BowTieXP Complete? Have a look at one of the scheduled events below or check the complete event calendar. If you can’t find a course of your interest, don’t hesitate to contact us via [email protected] or +31 (0) 70 362 6126 so we can help you find a suitable alternative.

Blog posts on this subject

Blog posts on this subjectWant to know more about LOPA, Spreadsheet, or quantification? We regularly write blog posts about this subject.

How would you recognize reoccurring key-lessons learned from over 200.000 annual safety reports? The solution: Big data text analysis for bowties. When you are dealing with a vast number of text-based safety records [...]

We're just a phone call away

We're just a phone call awayFeel free to call us with any questions you might have. Our enthusiastic support team is here to help you choose the solution best suited to your needs.

Call us now at +31 (0)70 362 6126 (09:00-17:00CET) or visit the Support section on our website.